Acrylic VS Polycarbonate

A Quantitative and Qualitative Comparison

Acrylic is often compared to polycarbonate, another transparent polymer sometimes used for bearing loads. Polycarbonate is sometimes called Lexan®, which is a trademark by Sabic. Another popular brand name for Polycarbonate is Makrolon®, owned by Bayer. Hammerglass® is another polycarbonate mainly used for security and against vandalism. Acrylic on the other hand is often called Plexiglas. Plexiglas® is a trademark by Evonik.

Comparison of Characteristics

Acrylic:

- More likely to chip

- Less impact-resistant than polycarbonate, yet still 10-24 times more resistant than float glass

- More resistant against evenly-distributed loads then polycarbonate

- Less likely to scratch.

- Does not degrade in colour to yellow after time.

- Better clarity. Acrylic can be restored to optical clarity by polishing.

Polycarbonate:

- Impact/chip resistance is about 30 times more resistant than glass

- More likely to scratch.

- Substantially more expensive. (Roughly 2 to 3 times)

- Used for more industrial applications

- Bulletproof when thick enough.

- More bendable under normal temperatures (0-20°C)

- Goes yellow over time due to UV rays

- Easier to work with

- Poorer clarity, diffuses light

| Polycarbonate – Lexan | Acrylic – Plexiglas GS | ||

| Density | g/cm³ | 1.2 | 1.19 |

| Max weight gain during immersion | % | 0.35 | 2.1 |

| Tensile strength σΜ at 23°C | MPa | 60-70 | 80 |

| Flexural strength σbB | MPa | 90 | 115 |

| Impact strength acU (Charpy) | kJ/m2 | 35 | 15 |

| Optical Light Transmission | % | 89 | 92 |

| Forming Temperature | °C | 185…205 | 160…175 |

| Vicat B Temperature | °C | 145 | 115 |

| Velocity of Sound | m/min | 2270 | 2750 |

| Attenuation at 5MHz | dB/cm | 24.9 | 6.4 |

| Fire Rating | German DIN 4102 | B2 | B2 (*2) |

Acrylic BLock

Popular Uses for Acrylic

- Motorcycle helmet visors

- Helicopter/submarine windows

- Spectator protection in ice hockey

- Modifications on police vehicles for riot control

- Swimming pool windows

- Aquariums and terariums (including large public aquarium walls and tunnels).

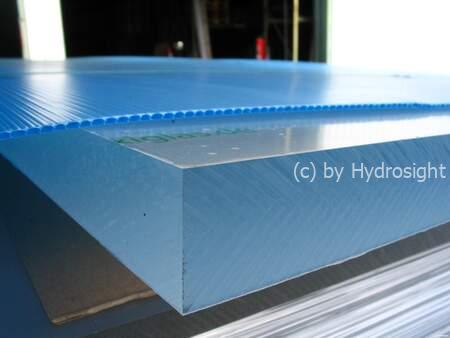

Acrylic is the right material for evenly distributed pressure. Image shows an underwater window by Hydrosight. Click for more examples.

Popular uses for polycarbonate

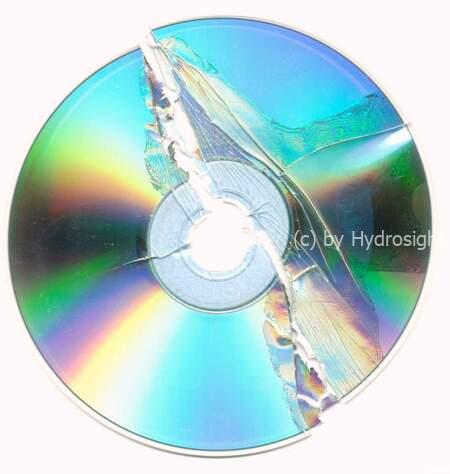

- Compact discs, DVDs

- Lighting lenses, sun-/eyeglass lenses, safety glasses, automotive headlamp lenses, camper windows

- Drinking bottles

- Computers, such as Apple

- Cases

- Riot shields, visors

- Instrument panels

- Bulletproof protection

Send me the new 2024 Hydrosight catalog

Send me the new 2024 Hydrosight catalog