Acrylic Windows vs Glass Windows

Acrylic glass is often chosen as an alternative for laminated glass. Both Acrylic and laminated glass are transparent building materials which withstand high pressures and can be used for applications like aquariums in marine museums and yacht windows.

Acrylic is a monolithic material made of organic substance, hence its nickname "organic glass". Plexiglas is a popular brand name for acrylic. Another one is Perspex©.

Laminated glass is made of several layers of mineral glass (also called flat glass, Borosilicate glass or "Echtglas"- real glass, in German). These sheets of glass are separated by transparent liners which are fused together. This makes them particularly strong and prevents inclusions. The materials used for the liner are PVB & SGP. Nowadays SGP is chosen for most applications, because of its hydrophobic properties.

Looking at different physical aspects we want to compare the performance of the two materials.

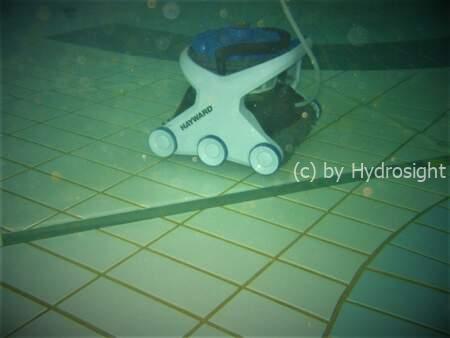

Hydrosight Underwater Window in a control room for a ROV. The water is just above 0°C, still there is no condensation on the screen.

Thermal Conductivity

The thermal conductivity of acrylic is lower than that of laminated glass. In other words the thermal insulation of acrylic is better than of laminated glass.

| Material | Insulation |

|---|---|

| Air | 0.03 W/mK |

| Acrylic | 0.19 W/mK |

| Water | 0.57 W/mK |

| Glass, Laminated | 0.79 W/mK |

Implications on Pool Underwater Windows:

- No condensation

- less heat loss of the pool water

- better insulation of heated buildings

Optical Transmission

When comparing optimized, thick structural glazing options:

- Laminated float glass made with four 12mm layers of low-iron glass and three SGP interlayers will have a VLT in the range of approximately 75% to 85%. This is a highly transparent result for such a robust, multi-layered safety glazing.

- Thick cast acrylic (PMMA), even at substantial structural thicknesses, typically maintains a VLT of above 88-90%.

Therefore, for maximizing visible light transmission in very thick structural glazing, cast acrylic (PMMA) generally offers a higher VLT compared to a multi-layered low-iron SGP laminated glass assembly of comparable structural capability. (see full comparision text)

Glass needs to be very thick and laminated in order to bear water pressure. It has a greenish tint. Acrylic is optically superior and has no visible tint.

Shattering and Cracking

Acrylic has a higher impact strength than glass and does not shatter when exposed to high strains. Shattering into small, blunt chunks is desirable for applications in which tempered glass is used, e.g. in automobiles.

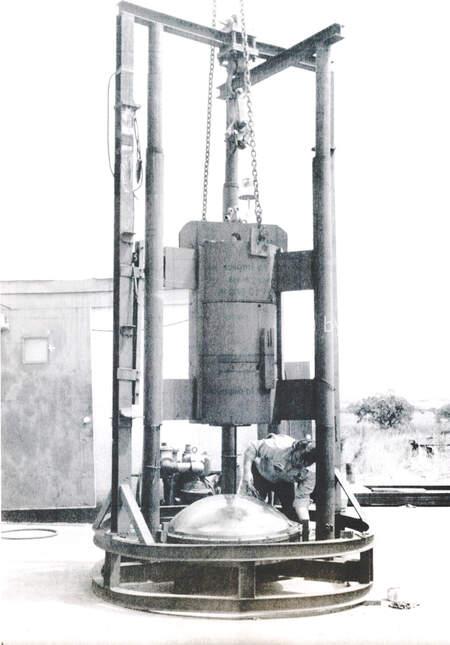

However, shattering is not desired for the use of glazing underwater. The crack resistance is especially valuable, when large underwater windows are craned into their location. The installation of large and heavy glazing bears a certain risk for the installation company when using laminated safety glass. Point loads while hanging on the crane or due to uneven seating might lead to material failure. Acrylic is more tolerant to these forces and rather flexes then breaks. Acrylic's high impact strength, durability and applicability make it the ideal material even when human lives are at stake. Therefore acrylic is used in deep sea submarine windows.

Polycarbonate is also a great, shatter-proof material.

Question: When it comes to the engineering of the window and the forces that it can take, we have to design for seismic conditions (earthquakes). When designing your windows do you consider any additional loads beyond the static water load?

Answer: Our windows are engineered with durability in mind, utilizing thick blocks of acrylic designed to withstand significant static hydrostatic loads, evenly distributed across their surface. While seismic conditions introduce dynamic vibration forces, the windows' substantial mass contributes to a high level of inertia, making them resistant to sudden movements. Unlike brittle materials such as glass, acrylic exhibits toughness comparable to steel, allowing it to flex under stress rather than shatter. This ability to bend rather than splinter enhances its resilience against seismic forces, ensuring structural integrity even during earthquakes. While the primary focus remains on hydrostatic loads, the inherent toughness and flexibility of the material provide an added layer of safety in dynamic conditions.

Impact test for an acrylic spheric window, with impact mass of 560kg. Courtesy of J.Stachiw.

Weight

Acrylic glass has a lower density, which can range from 1150-1190 kg/m³. This is less than half the density of glass which ranges from 2400 to 2800 kg/m³. Transportation and assembly of acrylic building materials is consequently easier and cheaper.

Installation of a Hydrosight Control Window for a Glacier Water Tank in Iceland.

UV Resistance

Using acrylic outdoors exposes the material to potentially high amounts of ultraviolet radiation (UV). It is a common misconception that UV rays lead to the yellowing of acrylic glazing. This might be true for low quality acrylic. Plexiglas and other well known brands are immune even against high UV radiation. Up to 30 years are guaranteed by the manufacturer.

Safety glass consists of multiple layers of mineral glazing, separated by plastic laminate. Normal plastic laminates are not resistant against UV and are especially sensitive to humidity.

Acrylic Pool Windows don't Mind UV - this one has been installed by Hydrosight in Italy.

Scratch Resistance

The surface of acrylic is softer and more prone to scratching than mineral glass. To prevent abrasive or chemical damage, it is advisable to check the acrylic cleaning guidelines. Acrylic can easily be polished to remove blemishes. In contrast, scuffed mineral glass would need to be completely replaced.

Conclusion

- Float glazing is less transparent then acrylic.

- Float glazing, safety glazing and tempered glass is inferior in bearing structural loads and might shatter.

- Safety glazing tends to delaminate when used under water.

- UV might be a problem for safety glazing.

There are view cases where safety glazing is a viable option, but in the vast majority of applications acrylic has proven to be superior when used for underwater.

Send me the new 2026 Hydrosight catalog

Send me the new 2026 Hydrosight catalog